✦

Traditional Chinese Medicine (TCM) pills, as a traditional dosage form, are characterized by ease of storage, prolonged efficacy, and convenient administration. Clinically, pills are formulated based on the properties, toxicity, disease nature, constitution, and conditions of the patient, making them suitable for the treatment of chronic diseases in their later stages. In recent years, a dual-mode approach has emerged, combining multiple technologies and exploring new processes, leading to significant advancements in excipient research, extraction processes, quality evaluation, drying, and microbial inactivation. This article systematically introduces the research progress on TCM pills over the past five years, aiming to provide references for their application in production.

✦

✦

Pills were first mentioned in the “Fifty-Two Disease Formulas” and are spherical dosage forms made from finely powdered medicinal materials or extracts combined with appropriate excipients. The two main theories of pills are “medicinal properties suitable for pills” and “diseases suitable for pill administration.” Common excipients include water, honey, starch, and beeswax, with dosage forms such as water pills, honey pills, water-honey pills, paste pills, wax pills, and drop pills. Preparation methods include the general method, plastic method, and drop method. With the development of modern testing methods and continuous improvements in formulation technology, new laboratory techniques are gradually being applied to production processes, continuously promoting innovation and exploration in pill production. This article systematically introduces the research progress on TCM pills over the past five years, focusing on the study of drugs and excipients, characterization methods for active ingredients, extraction production processes, drying and optimization plans for pills, and quality control.

Part

1

Excipient Research for Pills

1.1

Honey and Related Research

The 2020 edition of the “Pharmacopoeia of the People’s Republic of China” includes 192 types of honey pills, accounting for 11.9% of traditional pills, making honey the most important excipient in current traditional pills. Honey, as a primary excipient for pills, must be boiled until it becomes viscous before use, serving as the foundation for pill formation. Traditional honey refining is categorized into tender honey, medium honey, and old honey based on refining temperature and moisture content, but specific refining processes and quality standards are difficult to control. Wu Guorui et al.[1] compared moisture parameters with viscosity and density parameters to study honey refining quality, finding that moisture parameters are less affected by external factors and can directly characterize honey properties. Near-infrared spectroscopy can dynamically detect moisture changes during honey refining, allowing for rapid classification of three degrees of honey refinement. Du Panpan et al.[2] optimized the honey refining process using orthogonal experiments, determining that heating at 80-100°C for 9-12 minutes yields the best results, with the optimized honey refining process being stable and feasible. The agglomeration process is a key step in the plastic method of pill making; failure to agglomerate in a timely manner can lead to overly hard pills, affecting the quality of honey pills. Feng Xin et al.[3] established physical parameters reflecting the agglomeration process based on different resting times during the honey pill agglomeration process, noting significant changes in hardness and adhesion within 0-3 hours. High-performance liquid chromatography coupled with evaporative light scattering detection analyzed honey components, revealing that some honey in Bai Zi Yang Xin Wan exceeded 5% maltose, indicating adulteration; this method provides a reference for the quality evaluation of large honey pills.[4]

1.2

Main Drug-Related Excipients

The 2020 edition of the “Pharmacopoeia of the People’s Republic of China” includes over 40 drug-excipient homologous varieties, where the drugs in the formula can also serve as excipients. For example, honey in licorice powder honey soup acts as both an excipient and a main drug. The combination of excipients and formula drugs reflects the idea of “drug-excipient unity,” which utilizes the physicochemical properties of drugs to replace or reduce the use of excipients, significantly enhancing the efficacy and safety of formulations. The theory of drug-excipient unity is of great significance in exploring the dissolution rate, pharmacodynamics, and scientific connotations of formula compatibility and proportions. Chen Jianping et al.[5] optimized the preparation process of Jian Pi Yi Shen Wan based on pharmacodynamic models and the theory of drug-excipient unity, separately grinding five medicinal materials, including Bai Zhu (White Atractylodes), into fine powder, while the remaining medicinal materials, such as Huang Qi (Astragalus), were made into extracts, with the extract serving as an excipient for pill making. For the viscosity of the extract, a rotational rheometer can characterize concentrated extract liquids at different viscosity points, fully utilizing the physical properties of the main drug as an adhesive to prepare zero-excipient concentrated water pills[6], thus practically applying the theory of drug-excipient unity while achieving dynamic characterization of viscosity parameters. Li Li[7] explored the importance of physical parameters such as moisture absorption rate, water absorption rate, and specific viscosity under the theory of drug-excipient unity, indicating that physical parameter research is a necessary step in the design of new drug development based on drug-excipient unity, providing testing standards for scientifically formulating quality parameters.

1.3

Drop Pill Excipients and New Drop Pills

Drop pills have two types of matrices: water-soluble and water-insoluble. Currently, drop pill excipients mainly consist of polyethylene glycol and its mixtures, with near-infrared spectroscopy providing new ideas for quality evaluation and process control of medicinal excipients through classification and characterization of physical parameters. Xiong Haoshu et al.[8] established a method for measuring the viscosity index of PEG 6000 during the production of drop pills and used multivariate statistical analysis to screen for quality defects in PEG 6000, ensuring the stability of drop pills during storage. New drop pill excipients are primarily derived from optimized mixtures to select the best performance, enhancing flowability, stability, and disintegration performance by altering the physical properties of particles. Starch and xylitol are mixed in a 0.24:1 ratio as a new matrix for compound Danshen drop pills, enhancing the hardness of single xylitol excipients[9]. Drop pills combined with solid dispersions, nanoemulsions, self-microemulsions, and other intermediate carriers have produced enteric-coated and controlled-release drop pills, enriching the functionality of drop pill formulations and improving bioavailability and stability. Self-microemulsions are formed by mixing drugs, active agents, and lipid mixtures with water to create an emulsion, while solid dispersions refer to drugs uniformly dispersed in carriers to form solid intermediates. Wang Kexing et al.[10] combined solid dispersions with self-microemulsion drug release systems to prepare paclitaxel composite drop pills, improving bioavailability while addressing the issue of paclitaxel soft capsules becoming soft after prolonged storage. Enteric-coated drop pills and controlled-release drop pills modify or add coating materials based on drop pills; for instance, ibuprofen enteric-coated drop pills incorporate 10% polyacrylic acid resin as an enteric material, altering the release site and timing of the drop pills. Li Yongsheng et al.[11] utilized the property that the larger the molecular weight of the polyethylene glycol matrix, the lower the cumulative release of the drug, to prepare compound toad venom controlled-release drop pills, determining that the ratio of hydrophobic matrix PEG 4000 to hydrophilic matrix stearic acid is 5:1, achieving an in vitro release time of 12 hours, reducing the peak blood concentration of toad venom drop pills while mitigating toxicity.

Part

2

Pill Production Technology and Processes The small volume characteristic of drop pills necessitates that the active components must be extracted, achieving a purity of over 90% through the enrichment of effective components. Traditional extraction methods are complex, have low safety, are time-consuming, and have high energy consumption. The pulverization of TCM pieces and the extraction of effective components are the primary steps in pill preparation, crucial for enhancing the intrinsic quality and clinical efficacy of pills. The combination of multiple technologies, such as ultrasonic-supercritical CO2 extraction, ultrasonic enzymatic extraction, liquid-solid micro-extraction, ultrasonic microwave extraction, and semi-biomimetic enzymatic extraction, has shown significant advantages in optimizing extraction processes.

2.1

Pulverization and Its Research

Pulverization utilizes external energy to break the intermolecular cohesion to facilitate pill making, while also promoting the dissolution and absorption of drugs and accelerating the extraction of effective components. Pulverization methods include dry pulverization, low-temperature pulverization, wet pulverization, and ultrafine pulverization. However, nanoscale pulverization can lead to surface effects and quantum size effects that alter drug properties, causing particles to adsorb charges from the air, compromising effective components, and increasing the dissolution rate of toxic herbal components. During pulverization, particles can reaggregate into larger particles due to van der Waals forces and charge adsorption. Airflow pulverization-electrostatic dispersion technology produces composite ultrafine powders, where the Coulomb repulsion generated in an external electric field disperses particles, and higher voltages yield smaller particle sizes[12]. Zhang Qianliang et al.[13] studied the physical property characterization methods and physical fingerprinting of ultrafine pulverized Danshen slices, employing similarity analysis and multivariate statistical analysis for quality consistency evaluation, laying the foundation for improving the quality control level of Danshen wall-breaking quality. Wet pulverization extraction avoids high temperatures that can damage heat-sensitive components by pulverizing in a liquid or fluid state. This method demonstrated significantly better extraction time and yield for chlorogenic acid in honeysuckle compared to ultrasonic extraction and reflux extraction[14]. Zhang Aili et al.[15] optimized the airflow ultrafine pulverization of sea cucumber, where the optimal pulverization pressure was 0.77 MPa, and the feed speed was 227 r/min, resulting in smaller particle diameters compared to ordinary pulverization, thus shortening the dissolution time.

2.2

Extraction Technologies and Their Research

Electromagnetic cleavage utilizes electromagnetic waves to create a charge potential difference inside and outside cells, causing cell rupture at peak values for extraction. Wang Ringuang[16] established the optimal process for extracting related components from rhubarb, Chai Hu (Bupleurum), and Huang Qin (Scutellaria) using electromagnetic cleavage. Microwave extraction selectively heats substances with different dielectric constants, exciting them to a state that ruptures cells for subsequent extraction. Liu Yuan et al.[17] established the optimal process for microwave extraction of Angelica, with a liquid-solid ratio of 15:1, adding 50% ethanol, and extracting at 4 kW microwave power for 30 minutes. Low eutectic solvents, composed of hydrogen bond acceptors and donors, are renewable and designed as green solvents. Ultrasonic-assisted extraction employs 20-50 kHz sound waves to create uneven tearing in the extraction liquid, causing violent collisions between particles that rupture them, while the thermal energy generated by sound waves accelerates dissolution and diffusion. Li Jichao[18] utilized ultrasonic-assisted low eutectic solvent extraction to extract flavonoids from ginkgo leaves, with the low eutectic solvent being a mixture of choline chloride and ethylene glycol in a 1:4 molar ratio, achieving higher extraction rates than ethanol extraction under conditions of 39 minutes and 65°C. Semi-biomimetic extraction simulates the absorption of drugs in acidic and alkaline environments of the stomach, effectively separating mixed drugs and active components. Fan Baorui et al.[19] employed this method to extract active ingredients from Xia Ku Cao (Selfheal), combining biopharmaceutics with holistic drug research to simulate the gastrointestinal transport process of oral medications. Supercritical CO2 extraction alters pressure and temperature to maintain CO2 between gas and liquid states, serving as a safe solvent with no residue. Guo Qingyu[20] used supercritical CO2 extraction to obtain ginkgolides, achieving optimal extraction effects at 60 minutes, 45°C, and 21 MPa, ensuring no solvent residue and achieving extraction and separation in one step.

2.3

Production Process Optimization

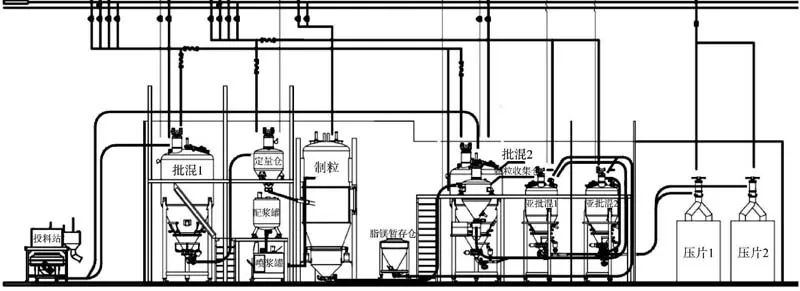

The more mature methods in production processes are uniform design and orthogonal experimental design, which can achieve optimal points during experimental processing. Liu Xianyang[21] utilized orthogonal experimental methods to determine the parameters for the mechanical agglomeration process of Er Cong Zuo Ci Wan, with a drug-honey ratio of 1:0.4, water addition of 7%, frequency ratio of 0.9, knife size of 5.2 mm, and drying at 75°C. However, the predictive capability of mathematical models established by orthogonal experimental design is poor, leading to insufficient precision in experiments and failing to sensitively investigate interactions between factors. Response surface optimization methods include Box-Behnken design and star point design, presenting optimized processes through multi-effect superposition in three-dimensional effects, with the obtained predictive models being continuous and directly readable for reference ranges of process conditions. Wang Yi et al.[22] optimized the preparation process of Qi Xue Shuang Bu drop pills based on the Box-Behnken response surface method, using extract density, matrix ratio, drop distance, and drop speed as reference values.

Part

3

Pill Drying Drying directly affects the external quality and internal quality of pills. Common drying methods include hot air drying, vacuum drying, and microwave drying. During the drying heat transfer process, thermal energy is transferred from the surface to the interior of the pills, with surface moisture vaporizing first, followed by internal moisture diffusing to the surface, with mass transfer and heat transfer occurring simultaneously. Common drying issues include reduced effective components, cracks, dry shells, false dryness, and uneven surfaces. When the amount of internal moisture diffusion is less than the amount of surface vaporization, uneven mass transfer leads to false dryness or cracking on the pill surface. Drying kinetics is calculated based on medium energy consumption, moisture evaporation, and time concerning drying rates. Studies have shown that the Weibull function model can characterize the moisture content, moisture diffusion coefficient, activation energy, and volume shrinkage characteristics of pills under different temperatures and drying methods, with vacuum drying taking less time than hot air drying, and slow drying resulting in reduced volume shrinkage[23]. Cao Qiufang et al.[24] analyzed the stability issues of pill cracking and solid dispersion drop pills from the perspective of glass transition temperature, indicating that adjusting drying temperature and drug load can prevent glass transition. Time-domain reflectometry is a technique for measuring soil moisture content, and Hou Xiaoya et al.[25] applied this method to establish a real-time online model for measuring moisture in Qi Ju Di Huang Wan, showing that drying at 60°C to 13.8% moisture, followed by heating to 80°C and continuing drying to 7.80%, then cooling to 60°C, can achieve the target moisture content. Shi Xinhua et al.[26] optimized the microwave drying process for Fu Ning Wan, where the material transfer speed was 0.4 m/min, material thickness was 6 mm, and drying temperature was 70°C, meeting the specified indicators for dissolution time, moisture content, and microbial limits. Meng Jiansheng et al.[27] compared infrared drying, vacuum pulse drying, and gas jet impact drying, indicating that gas jet impact drying had the shortest drying time for yam, with minimal changes in indicator components and optimal color, while infrared drying was the least effective.

Part

4

Quality Evaluation The quality evaluation of pills primarily examines active components, in vitro and in vivo release, and microbial content. The technology and methods of the quality control system for pills have been comprehensively enhanced, with multi-technology combinations widely applied in the quality control of TCM preparations.

4.1

Detection of Active Components

Lian Yunfang et al.[28] conducted pharmacodynamic studies on six batches of Flavonoid-Reducing Drop Pills made from Daitai fruit and the active component groups of the original drugs, finding that the average overall migration similarity of the sample’s active component groups was similar to that of the original drug’s overall migration, indicating that the pharmacodynamics of the drop pills were close to those of the raw materials. Electrochemical fingerprinting utilizes the different responses of substances to chemical oscillation systems to obtain electrochemical fingerprints of TCM, characterizing the complex components of TCM. Wang Dongyan[29] established a new approach for rapid identification and auxiliary control of the quality of Sanqi drop pills using electrochemical fingerprinting. Zhu Chun et al.[30] established a quality identification model based on three-dimensional fluorescence spectroscopy, which three-dimensionally visualizes spectral graphs, effectively distinguishing different component spectra in superimposed states, thus enabling qualitative quality analysis of Liu Wei Di Huang Wan. Lei Feifei et al.[31] linked microbial activity with the dose-effect relationship of drugs, using the physiological activity and number of microbes over a period as a reference to indirectly characterize the content of major active components in compound Danshen drop pills, allowing for dynamic tracking and detection throughout the process. The one-measure-multiple-evaluation method establishes a connection between the effective components of a single drug and the remaining drug content, using intrinsic functional or proportional relationships as a bridge to measure one component while achieving simultaneous characterization of multiple components, characterized by simplicity and precision. Zhang Ling and Zhou Hui[32] employed a multi-point calibration method to establish a connection between paeoniflorin and nine other compounds, enabling simultaneous measurement of active components in Xuefu Zhuyu Wan.

4.2

Microbial Inactivation

Microbes originate from raw slices and the processing of TCM, significantly impacting the storage, quality stability, safety, and efficacy of pills. Sterilization quality is considered from the perspectives of sterilization rate, process parameters, chemical component content, pharmacological effects, moisture absorption, and disintegration. Common sterilization methods include radiation sterilization (irradiation, microwave, ultrasound, ultra-high pressure pulse), chemical methods (ozone, ethylene oxide, ethanol), and thermal sterilization (dry heat, moist heat (steam pressure, low-temperature intermittent, circulating steam)).60Co-γ radiation sterilization has strong penetration, maintaining dosage form stability, suitable for volatile and heat-sensitive TCM, and requires no post-sterilization treatment. High doses of 60Co-γ radiation can alter the chemical composition, pharmacological functions, and active substances, necessitating strict control of irradiation time and dosage, as the detection technology for irradiation residues is still immature, and no unified quality evaluation and testing standards have been established in the industry. Chen Weisheng et al.[33] studied the reasonable irradiation dosage for TCM, indicating that the established irradiation dosage for pills is 50%-88% lower than the actual dosage, and current irradiation standards are not recommended for pills. Microwave sterilization ensures uniform heating of pills, good expansion, and a clean, smooth appearance, effectively penetrating to sterilize the interior of pills, with high heat generated by the electric field causing protein denaturation and death, while ions in bacteria form capacitive structures in the electromagnetic field, leading to membrane potential and polar molecular structure breakdown. Zhang Fang et al.[34] explored the optimal process for microwave drying and sterilization of Angelica, with a moisture content of 15%, microwave power of 12 kW, microwave rotation speed of 1030 r/s, and sample load of 10 kg/m2, effectively reducing the loss of ferulic acid while achieving effective sterilization. Tunnel-type microwave drying sterilization machines can perform simultaneous drying and sterilization of pills, with tests on Ren Dan Wan validating the advantages of infrared radiation temperature measurement, stepless variable frequency speed regulation, and automatic microwave heating functions equipped in tunnel-type microwave drying sterilization machines[35]. Conventional instant high-temperature sterilization can cause powders to re-clump into blocks, while the instant sterilization technology developed by Tongrentang combines steam technology with instant decompression, achieving strong sterilization effects in 0.2 seconds, preventing powder clumping in a decompressed environment, avoiding oxidation reactions in an anaerobic state, and minimally affecting heat-sensitive components, demonstrating good sterilization effects[36].

4.3

In Vitro and In Vivo Release

Different types of pills exhibit variations in dissolution diffusion and absorption rates due to their different excipients. The dissolution of pills is closely related to the physicochemical properties of the drugs, particle size, honey refining degree and dosage, honey temperature during mixing, drying degree, and excipient disintegration. When particle size exceeds a critical value, instability leads to reduced dissolution rates. Water pills exhibit capillarity and porosity, allowing them to absorb water and swell for dissolution, while honey pills, concentrated pills, and paste pills form a thick immersion layer after surface wetting, hindering moisture penetration. Within a certain range, smaller particle sizes correlate with higher dissolution rates. Li Yuehui et al.[37] compared the dissolution parameters of Nu Zhen Zi (Ligustrum lucidum) in ultrafine pulverized Er Zhi Wan, finding significant differences between ultrafine pulverization and ordinary pulverization. Ye Yingxiang et al.[38] conducted a visual analysis of the release kinetics of Liu Wei Di Huang Wan with different excipients, revealing that water pills and concentrated pills released the fastest, with optimal release amounts and rates, while wax pills exhibited a gradual release curve initially, accelerating in the later stages. Zhang Wei[39] discussed the impact of drying temperature on the dissolution time of pills, indicating that cooling drying at 70°C can meet dissolution time requirements.

Part

5

Discussion and Outlook The current phase marks a critical transition from extensive production to refined high standards, with the latest achievements in pill production still in the laboratory trial stage, involving multiple disciplines such as medicinal chemistry, pharmacology, physical chemistry, and mechanical equipment. Research remains lagging, and further theoretical exploration and refined industry standards are needed to optimize and improve pill processing methods. The theory of drug-excipient unity is still a weak link in the scientific connotation research of formula compatibility, pharmacodynamics, pill production, and quality inspection standards[40]. The combination of new drop pills with solid dispersions, nanoemulsions, self-microemulsions, microcapsules, and liposomes has enhanced bioavailability, but drop pills typically weigh around 30 mg, with the matrix accounting for 30%-50% of the pill weight, affecting the drug load and resulting in a higher number of pills to be taken. Moreover, current drop pill formulations primarily consist of formulas with fewer than four ingredients, thus researching large drop pill technology could increase drug load while providing the possibility of formulating drop pills with more than four ingredients. The utilization of classic formulas is far less than in Japan and South Korea, and large drop pills are significant for expanding the number of ingredients in formulas and the secondary development of TCM. Formulating Gua Lou Xie Bai Ban Xia Tang into Gua Lou Xie Bai Ban Xia drop pills can reduce the dosage for patient convenience, which is significant for enhancing the utilization of classic formulas. The control release, rapid release, and targeted release of excipients are closely related to drop pills, necessitating enhanced research on the physical parameters and chemical properties of excipients concerning drop pill functionality, gradually establishing a quality control evaluation system for excipients to promote the integration of drop pills with new dosage forms[41]. In terms of stability, exploratory research on surfactants, disintegrants, and anti-oxidants in drop pill modifications should be gradually established to inhibit drug molecule aggregation and improve stability. Paste pills and wax pills are similar to modern hydrophilic skeleton formulations and bio-erodible skeleton formulations[42], which can mitigate adverse reactions of toxic or irritating drugs, playing a special role in pills. The addition of beeswax, lard, and animal viscera as hydrophobic excipients in pill production can rival modern nanoemulsion technology, as nanoemulsions are unstable thermodynamic systems that still have certain defects. Comparative studies between modern controlled-release technologies and traditional hydrophobic excipients lack systematic in-depth exploration. Additionally, the traditional excipient beeswax is relatively expensive, and no significant results have been seen in developing new alternative excipients, while the drug release mechanism of wax pills has not been thoroughly studied. Currently, the market share of wax pills is extremely low, and as traditional controlled-release pills, they hold significant importance; completing the modernization of wax pills is a key breakthrough needed in pill production. The wax shells in honey pill packaging are made from materials mixed with paraffin, serving to prevent corrosion, insect damage, and moisture absorption, but the extraction of wax shells from crude oil is non-renewable. Research should focus on de-waxing studies, combining capsule formulation shell materials with honey pills, utilizing new materials such as starch, cellulose, and water-soluble polysaccharides, achieving preservation against corrosion, insect damage, and moisture absorption through coating treatments. In terms of modern technology applications, comprehensive and three-dimensional exploration is crucial for the modernization of pills. In drug pulverization and extraction, ultrafine processing and multi-technology combinations have become new trends, necessitating the integration of different physicochemical properties of drugs to select optimal parameters for temperature, pressure, radiation, sound waves, and magnetic fields for research on drug pulverization and extraction processes, first classifying and refining based on the physicochemical properties of medicinal materials for ease of study. The study of the physicochemical parameters of ultrafine processed TCM powders will also impact the stability and utilization of formulations, as the increased dissolution of toxic components during ultrafine pulverization and changes in pharmacodynamics, as well as the electrostatic treatment of TCM powders in microenvironments, require further exploration. Most TCMs are plant-based, advocating enzymatic methods as the first step in extraction to efficiently and safely enhance extraction rates, followed by optimizing combinations of methods such as electromagnetic cleavage, supercritical extraction, ultrasonic microwave extraction, swirling extraction, and pressurized countercurrent extraction to maximize the retention of original efficacy and efficiently extract high concentrations of active components. The aforementioned extraction methods have been widely applied but still lack standardized extraction guidelines. Additionally, the application of TCM flocculation separation technology and membrane extraction separation technology is limited; both can be used as combined technologies, where flocculation separation allows unstable micro-particles to settle into flocculent aggregates, followed by membrane extraction separation technology, utilizing differences in molecular weight and charge properties to achieve separation. The combination of TCM flocculation separation and membrane extraction separation technology is suitable for heat-sensitive substances. The semi-biomimetic extraction technology that has emerged in recent years simulates the environment of oral drug transport and absorption in the gastrointestinal tract from a biopharmaceutical perspective, employing guided separation methods, with the content of active ingredients and monomer components serving as indicators, aligning with the targeted direction of drop pills. In addition to the currently widely used multi-technology combinations in drying processes, other processing methods such as freeze-drying, heat pump drying, and gas jet impact drying can also be referenced. Spray drying and freeze-drying are suitable for pills containing heat-sensitive drugs, as proteins and vitamins do not denature at low temperatures, heat-sensitive components do not volatilize, and microorganisms lose their biological activity. Heat pump drying utilizes a heat pump’s dehumidification and heating circulation system for relatively gentle drying, improving issues of cracking and uneven surfaces. Gas jet impact drying has a heat transfer coefficient an order of magnitude higher than that of general hot air, effectively improving drying efficiency. In terms of production efficiency for pills, how to combine pulverization sterilization and drying sterilization will undoubtedly become a new hotspot.Currently, multi-technology combinations are still limited to the production step of pills, and a comprehensive system should gradually be established from point to surface, encompassing the processing of medicinal slices, pill production, quality standard control, efficacy, and safety evaluation. The serial research of multi-technology combinations provides strong support for the modernization transformation of pills. As the theoretical and practical aspects of TCM pill production continue to improve, pills will undoubtedly have broader development space and application prospects.

References

[1] Wu Guorui, Xian Jiechen, Lin Xiao, et al. Characterization of Physical Properties of Honey Refining in TCM Excipients and Analysis of Correlations Between Parameters [J]. Chinese Journal of Experimental Formulas, 2014, 20(6): 1-5.

[2] Du Panpan, Yan Caiyun, Bai Zongli, et al. Research on Honey Refining Process in TCM Processing Excipients [J]. Asia-Pacific Traditional Medicine, 2017, 13(24): 27-29.[3] Feng Xin, Xu Bing, Du Jing, et al. Research on Physical Property Parameter Characterization Methods in the Agglomeration Process of Honey Pills [J]. World Science and Technology – Modernization of Traditional Chinese Medicine, 2015, 17(1): 272-277.[4] Zhao Wen, Yuan Mingming, Xu Yan, et al. Quality Study of Honey Refining in Bai Zi Yang Xin Wan [J]. Drug Evaluation, 2020, 17(13): 33-35, 38.[5] Chen Jianping, Chen Qiugu, Hu Zhaoliu, et al. Optimization of the Preparation Process of Jian Pi Yi Shen Wan Based on Pharmacodynamic Screening and Orthogonal Experiments [J]. Chinese Herbal Medicine, 2018, 49(24): 5817-5822.[6] Zhang Xue, Hu Zhiqiang, Lin Xiao, et al. Research on the Preparation of “Zero Excipient” TCM Concentrated Water Pills Based on the Correlation Between Concentrated Liquid Viscosity and Formulation Quality [J]. Chinese Journal of Traditional Chinese Medicine, 2021, 46(15): 3772-3779.[7] Li Li. Research on the Classification of TCM Materials Based on the Theory of “Drug-Excipient Unity” [D]. Zhengzhou: Henan University of Traditional Chinese Medicine, 2016.[8] Xiong Haoshu, Zhang Kaixuan, Li Yaoyao, et al. Research on Quality Control Methods of Medicinal Excipients PEG 6000 Based on Multivariate Statistical Analysis [J]. Journal of Pharmaceutical Analysis, 2021, 41(2): 329-337.[9] Sun Qing, Zhang Xiaojie, Wang Wei. Screening of Natural Matrix Excipients for Compound Danshen Drop Pills [J]. Journal of Pharmaceutical Practice, 2013, 31(4): 293-295.[10] Wang Kexing, Qin Cuiying, Han Jing, et al. Preparation and In Vitro Release Investigation of Paclitaxel Self-Microemulsion Drop Pills [J]. Journal of Pharmaceutical Practice, 2016, 34(4): 330-333.[11] Li Yongsheng, Wu Meijia, Jiang Shanshan, et al. Preparation and In Vitro Release Performance Investigation of Compound Toad Venom Controlled-Release Drop Pills [J]. Chinese Journal of Experimental Formulas, 2017, 23(8): 7-12.[12] Yin Pengfei. Research on the Preparation of Composite Ultrafine Powders Using Airflow Pulverization/Electrostatic Dispersion [D]. Xi’an: Northwestern Polytechnical University, 2015.[13] Zhang Qianliang, Luo Zheng, Deng Wen, et al. Quality Evaluation of Physical Properties of Wall-Breaking Danshen Slices [J]. Chinese Journal of Experimental Formulas, 2020, 26(23): 145-152.[14] Huang Jianqiong. Observation of the Effects of Wet Pulverization Extraction Method on Effective Components of TCM [J]. Journal of Clinical Rational Drug Use, 2015, 8(7): 3-4.[15] Zhang Aili, Xu Zhongkun, Zhang Qingfen, et al. Optimization of Airflow Ultrafine Pulverization Process for Sea Cucumber and Comparison of Related Indicators Before and After Pulverization [J]. Chinese Medicine, 2016, 38(1): 58-62.[16] Wang Ringuang. Research on a New Electromagnetic Cleavage Technology in the Extraction of TCM Rhubarb, Huang Qin, and Chai Hu [D]. Changchun: Changchun University of Traditional Chinese Medicine, 2019.[17] Liu Yuan, Shi Xiaomeng, Wang Zhengkuan, et al. Research on the Application of Microwave Technology in the Extraction Process of Angelica [J]. Modern Chinese Medicine, 2016, 18(11): 1490-1493, 1512.[18] Li Jichao. Research on the Extraction and Purification of Flavonoids from Ginkgo Leaves Using Low Eutectic Solvent [D]. Beijing: Beijing University of Chemical Technology, 2020.[19] Fan Baorui, Ma Fengbo, Liu Hui, et al. Semi-Biomimetic Method for Extracting Ursolic Acid and Oleanolic Acid from Xia Ku Cao [J]. Journal of Hebei University: Natural Science Edition, 2019, 39(6): 605-610.[20] Guo Qingyu, Fu Baohui, Cao Dan. Research on the Extraction of Ginkgolides B Using Supercritical CO2 [J]. China Petroleum and Chemical Standards and Quality, 2020, 40(24): 109-112.[21] Liu Xianyang. Research on the Mechanical Pill Making Process of Er Cong Zuo Ci Wan and Verification of Production Process [D]. Shanghai: Shanghai Jiao Tong University, 2017.[22] Wang Yi, Chen Linwei, Wang Hua, et al. Optimization of the Best Forming Process for Qi Xue Shuang Bu Drop Pills Based on Box-Behnken Response Surface Method [J]. Chinese Pharmacist, 2019, 22(2): 241-244.[23] Wang Xuecheng, Kang Chaochao, Wu Zhenfeng, et al. Simulation and Kinetic Analysis of the Drying Process of Liu Wei Di Huang Wan Based on the Weibull Function Model [J]. Chinese Journal of Experimental Formulas, 2019, 25(12): 133-139.[24] Cao Qiufang, Rao Xiaoyong, Zhang Yao, et al. Research Progress on the Application of Glass Transition Phenomenon in Pharmaceutical Sciences [J]. Acta Pharmaceutica Sinica, 2021, 56(5): 1301-1313.[25] Hou Xiaoya, He Fanghui, Sun Xiaomei, et al. Real-Time Online Measurement of Moisture in Qi Ju Di Huang Wan Drying Process Using Time-Domain Reflectometry and Optimization of Drying Process [J]. Chinese Herbal Medicine, 2020, 51(10): 2767-2772.[26] Shi Xinhua, Li Yuan, Liang Weijun, et al. Orthogonal Experimental Study on Microwave Drying of Fu Ning Wan [J]. Journal of Traditional Chinese Medicine, 2013, 24(11): 2661-2663.[27] Meng Jiansheng, Jiang Junchen, Zheng Zhian, et al. Effects of Three Drying Methods on the Drying Kinetics and Quality of Yam Slices [J]. Chinese Herbal Medicine, 2019, 50(11): 2575-2582.[28] Lian Yunfang, Chen Dan, Huang Qun, et al. Overall Migration Rate of Active Component Groups in Daitai Fruit Flavonoid-Reducing Drop Pills During Preparation [J]. Chinese Medicine, 2018, 40(5): 1078-1082.[29] Wang Dongyan. Preparation and Quality Control of Sanqi Drop Pills Using Electrochemical Fingerprinting [D]. Jiamusi: Jiamusi University, 2018.[30] Zhu Chun, Zhao Jincheng, Xie Xin, et al. Quality Evaluation Study of Liu Wei Di Huang Wan Based on Three-Dimensional Fluorescence Spectroscopy [J]. Journal of Heilongjiang University of Science and Technology, 2015, 32(6): 810-814.[31] Lei Feifei, Wang Jianchun, Zhang Yongmei, et al. Preliminary Study on the Application of Real-Time Cell Electronic Analysis in Quality Evaluation of Compound Danshen Drop Pills [J]. Chinese Medicine, 2015, 37(5): 1119-1123.[32] Zhang Ling, Zhou Hui. Application of One-Measure-Multiple-Evaluation Method in Quality Evaluation of Xuefu Zhuyu Wan [J]. Chinese Herbal Medicine, 2018, 49(7): 1588-1593.[33] Chen Weisheng, Jian Minqian, Guan Qianming, et al. Preliminary Study on the Reasonable Irradiation Dosage for Sterilization of TCM [J]. Journal of Nuclear Agriculture, 2017, 31(8): 1515-1520.[34] Zhang Fang, Kang Sanjiang, Zhang Yongmao, et al. Optimization Study of Microwave Drying and Sterilization Process for Angelica [J]. Modern Chinese Medicine, 2017, 19(10): 1461-1465, 1475.[35] Teng Hongming. Confirmation of Temperature Distribution and Product Quality Indicators in Tunnel-Type Microwave Drying Sterilization Machines [J]. Electromechanical Information, 2017(11): 14-17.[36] Chi Yuming, Xie Suflower, Yao Lu, et al. Research and Industrial Application of New Sterilization Technology for TCM Raw Powders [J]. Innovation World Weekly, 2021(1): 86-93.[37] Li Yuehui, Xiao Juan, Cai Ping, et al. Effects of Ultrafine Pulverization Technology on the Dissolution Rate of Er Zhi Wan [J]. International Journal of Pharmaceutical Research, 2015, 42(5): 654-657.[38] Ye Yingxiang, Chen Ye, Weng Xiameng, et al. Visual Analysis of the Release Kinetics of Liu Wei Di Huang Wan with Different Excipients [J]. Chinese Herbal Medicine, 2017, 48(21): 4425-4431.[39] Zhang Wei. Discussion on the Impact of Drying Temperature on the Dissolution Time of TCM Pills [J]. China Medical Guide, 2019, 17(36): 10-11.[40] Zhang Dingkun, Fu Chaomei, Lin Junzhi, et al. “Drug-Excipient Unity” in TCM Preparations and Its Application Value [J]. Chinese Herbal Medicine, 2017, 48(10): 1921-1929.[41] Chen Lei, Song Zonghua, Hu Shujun, et al. Overview of the 2020 Edition of the “Pharmacopoeia of China” Medicinal Excipients Standard System and Main Features [J]. Chinese Journal of Pharmacy, 2020, 55(14): 1177-1183.[42] Zhao Lihua. Application of Controlled-Release Skeleton Materials in Formulations [J]. Medical Herald, 2008, 27(7): 827-829.

Authors | Liu Liwei, Cui Xin, Lu Ningning, Lü Jiajie, Fan Yipin, Yu Damei

Editor | Hu Jing

Reviewer | He Fa

Must-Watch Video

Recommended Reading

Application of Intelligent Continuous Production Mode in the Health Product Industry

How Biopharmaceutical Companies Can Transform and Design Aseptic Filling Workshops

Factors Affecting Cleanliness in Clean Rooms

This article is authored by Liu Liwei, Cui Xin, Lu Ningning, Lü Jiajie, Fan Yipin, Yu Damei from the Institute of Clinical Basic Medicine, China Academy of Chinese Medical Sciences, Hebei Agricultural University, Nanjing University of Chinese Medicine, and is sourced from World Traditional Medicine, for educational exchange only. Compiled and published by the “Pharmaceutical Technology and Equipment” platform, copyright belongs to the original authors. If there is any infringement, please contact for removal. Follow the “Pharmaceutical Technology and Equipment” public account for the latest innovations, news, and hot topics in the pharmaceutical industry.