Author: Li Feng

Reviewed by: Yan Guojun

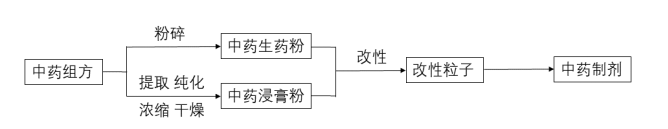

Traditional Chinese Medicine (TCM) powder has historically been an important method of using medicinal materials, accounting for a significant proportion of total prescriptions. For example, traditional powdered formulas are directly used in TCM, and most pills are prepared from finely powdered medicinal materials. With the development of powder processing technology, modern TCM preparations utilize medicinal powders as intermediate raw materials or finished products, altering the traditional coarse, dark appearance of TCM. By increasing the specific surface area of the drug particles, the solubility and bioavailability of TCM can be improved. Below, we will introduce the dosage forms of TCM powders for external use and the technology for powder modification.

Dosage Forms of TCM Powder

✦✦

1

TCM Powder Formulations

Powder formulations are one of the earliest forms of TCM powders, referring to a powder preparation made from one or more medicinal materials. The earliest records of powder formulations can be found in the “Fifty-Two Disease Formulas,” which contains 283 existing medical formulas, including 28 powder formulations. Powder formulations are divided into external and internal use powders, with external powders generally sprinkled on wounds or affected areas, such as Shengji San (生肌散) and Jinhuang San (金黄散); there are also external powders for throat blowing and eye drops, such as Bingpeng San (冰硼散) and Babao Eye Medicine (八宝眼药).

▲ Jinhuang San

2

Micronized and Nanoparticle TCM

Since the late 1990s, ultrafine grinding technology has been widely applied in TCM, which is based on TCM theory and the characteristics of medicinal materials, using modern powder technology to micronize TCM materials and extracts. This technology can improve the uniformity of TCM preparations, enhance inter-batch stability, accelerate the release of active components, and increase the rate of absorption. TCM ultrafine preparations such as micronized and nanoparticle TCM have attracted significant attention in the scientific and TCM communities.

TCM Powder Modification Technology

✦✦

The physicochemical properties of TCM powders are complex, often existing in an amorphous powder form. They typically exhibit poor flowability, high hygroscopicity, high viscosity, and poor wettability, which affect the production process and efficacy of TCM preparations. Thus, TCM powder modification technology has emerged, which is crucial for achieving standardized quality control and modernizing dosage forms of TCM preparations.

Powder modification refers to the treatment of powder particles using physical and chemical methods to purposefully alter their physicochemical properties, such as surface atomic layer structure and functional groups, hydrophobicity or hydrophilicity, electrical properties, and chemical adsorption and reaction characteristics, thereby enhancing the applicability of the powder.

Currently, the main methods used for powder modification include ultrafine grinding technology, physical surface modification technology, mechanical-chemical modification technology, and particle design technology.

1

Physical Modification Technology

① Ultrafine Grinding TechnologyUltrafine grinding technology crushes most intact cells in ordinary powders into cellular-level powders, resulting in significant changes in properties such as flowability and hygroscopicity, which have a marked impact on the formulation and in vivo and in vitro properties. Some researchers compared the physicochemical properties of rhubarb fine powder and ultrafine powder, showing that ultrafine grinding significantly affects the flowability of rhubarb powder, increasing its adhesion and reducing flowability, while the moisture absorption curve is similar to that of fine powder, and the amount of effective components in rhubarb does not decrease with the reduction of powder particle size, which is beneficial for the dissolution of effective components in rhubarb.② Surface Coating TechnologySurface coating, also known as surface covering or surface layering, involves no chemical reaction between the surface modifier and the particle surface, with the coating material connected to the particles through physical methods or van der Waals forces. Common surface modifiers include surfactants, super dispersants, and inorganic materials, with methods such as spray drying, fluidized bed, mechanical mixing, powder deposition, and mechanical grinding. For example, Feng Yi et al. produced microcapsules of wuyou tannin using spray drying technology, finding that the modified wuyou tannin reduced the hygroscopicity of the drug itself.

Traditional Chinese Medicine Powder

2

Chemical Modification Technology

① Wet Mechanical-Chemical ModificationWet mechanical-chemical modification refers to the interaction of powders with modifiers in a solid-liquid environment, subjected to mechanical forces such as extrusion, shear, and impact, activating the powder surface, which then undergoes physical and chemical reactions with the modifiers, characterized by good dispersion and uniform coating. For instance, Di Liuqing et al. used astragalus extract powder as a model drug, mixing it with different modifiers in an ethanol medium, and found that 7% acrylic resin and 5% stearic acid as modifiers provided better moisture-proofing effects, indicating that wet mechanical-chemical modification effectively improved the moisture resistance of astragalus extract powder.② Dry Mechanical-Chemical ModificationDry mechanical-chemical modification is conducted in a single solid phase environment, which, compared to wet methods, has advantages such as simplicity, shorter modification time, and higher efficiency. For example, Qin Chunfeng et al. used 3%, 5%, and 7% doses of micronized silica gel as modifiers for the grinding modification of angelica extract powder, showing that the modified powder had increased micropore volume, enhanced water absorption, and accelerated dissolution rate.

Traditional Chinese Medicine Powder

3

Particle Design Technology

In recent years, some researchers have proposed TCM particle design technology based on the characteristics of physical and chemical modification technologies, which involves structural and functional design of powders at the microscopic level according to the physicochemical properties of TCM powders, guided by the concept of “drug-excipient integration” to enhance powder performance. For instance, Zhang Dingkun et al. used particle design technology to prepare oral ulcer powder, finding that the powder properties of the particle-designed formulation were superior to those of ordinary powders and ultrafine powders.

Traditional Chinese Medicine Powder

Conclusion

With the continuous improvement of new technologies and theories for TCM powder modification, the application range of TCM external preparations in powder form is expanding, playing an increasingly important role in the treatment of clinical diseases, especially in dermatological conditions.

References

[1] Yang Zerui, Peng Lihua, Deng Wen, Cheng Jinle. Overview of the Development History of TCM Powders. Anhui Agricultural Sciences, 2016, 44(12): 141-143+145. DOI:10.13989/j.cnki.0517-6611.2016.12.045.

[2] Jiang Qieying, Zeng Ronggui, Zhao Guowei, Luo Yun, Lü Dan, Kong Xiaoqiang, Liao Zhenggen. Research Progress on TCM Powder Modification Technology and Equipment. Chinese Herbal Medicine, 2017, 48(08): 1677-1681.

[3] Fang Hegui. Dosage Forms Suitable for External Use of TCM: Gels. China Pharmaceutical Industry, 2002(08): 25-26.

[4] Chen Wei, Li Jianhua, Xia Yu, Yang Zhengwang. Research Progress on TCM Formula Granules for External Use. China Prescription Drugs, 2020, 18(08): 18-21.

[5] Liu Huimin, Liu Yuming, Chen Xiangqi, Shen Xianrong. Clinical Applications and Research Progress of TCM External Preparations in Skin Diseases. Modern Research and Practice of TCM, 2014, 28(04): 70-73. DOI:10.13928/j.1673-6427.2014.04.058.

[6] Yang Zerui, Peng Lihua, Deng Wen, Cheng Jinle. Overview of the Development History of TCM Powders. Anhui Agricultural Sciences, 2016, 44(12): 141-143+145. DOI:10.13989/j.cnki.0517-6611.2016.12.045.

[7] Zhao Guowei, Wang Chunliu, Cao Yunchao, Liao Zhenggen, Liang Xinli, Zhao Lijun. Comparison of the Physicochemical Properties of Rhubarb Fine Powder and Ultrafine Powder. Chinese Hospital Pharmacy Journal, 2012, 32(16): 1252-1255.

[8] Wang Jing. Research on Powder Modification and Particle Recombination in TCM Preparations. Biotechnology World, 2015(03): 101.

[9] Feng Yi, Liu Yi, Xu Desheng. Discussion on Factors Affecting the Moisture-Proof Effect of Microcapsules and Their Mechanisms. Chinese Journal of Traditional Chinese Medicine, 2007(14): 1409-1412.

[10] Zhang Dingkun, Qin Chunfeng, Han Li, Lin Junzhi, Wang Nianming, Guo Zhiping, Yang Ming. The Effect of Particle Design on the Powder Properties of Oral Ulcer Powder. Chinese Journal of Traditional Chinese Medicine, 2013, 38(03): 334-340.

Copyright Notice

Reprint with source indicated:

Herbal Medicine External Use (ID: EATCM-NJUCM)

Reprinting is the driving force for creation, sharing is the starting point for cooperation.

Image Source: Baidu Image Library

Editor: Li Feng, Yao Junhong

Scan to Follow Us

Scan to Follow Us Your sharing keeps me energized!

Your sharing keeps me energized!